Impeller (301)

High-Performance Impeller Manufacturing

Client

Automotive Supplier

Year

2023

Complex Geometry with Optimized Flow Dynamics

Our client needed automotive impellers with complex curved geometries optimized for maximum flow efficiency. The challenge was maintaining precise blade angles and surface finish while using glass-filled nylon for strength and durability.

The impeller design featured intricate flow channels and varying wall thicknesses that were difficult to mold consistently. Any dimensional variations could significantly impact performance and cause vibration issues.

High-volume automotive production required robust processes capable of producing 75,000+ units annually with zero tolerance for defects.

Advanced Injection Molding with Flow Optimization

Stone Plastics developed a specialized injection molding process using glass-filled nylon with optimized flow characteristics. We created complex tooling with advanced cooling systems to manage the varying wall thicknesses.

Our engineering team used flow analysis software to optimize gate placement and injection parameters. The process includes real-time monitoring of key parameters to ensure consistent part quality.

The solution included: • Complex multi-cavity tooling with advanced cooling • Glass-filled nylon material optimization • Flow analysis and gate placement optimization • Real-time process monitoring and control • Automated balancing and flow testing • Statistical process control implementation

Key Outcomes

75,000+ impellers produced annually

±0.002 inch tolerance on critical dimensions

15% improvement in flow efficiency vs. previous design

Zero warranty claims for vibration issues

20% reduction in material waste through optimization

Stone Plastics' expertise in complex geometry molding has been exceptional. The impellers consistently meet our stringent performance requirements and have helped improve our overall system efficiency.

Robert Kim

Senior Engineer, Automotive Dynamics Corp

Project Gallery

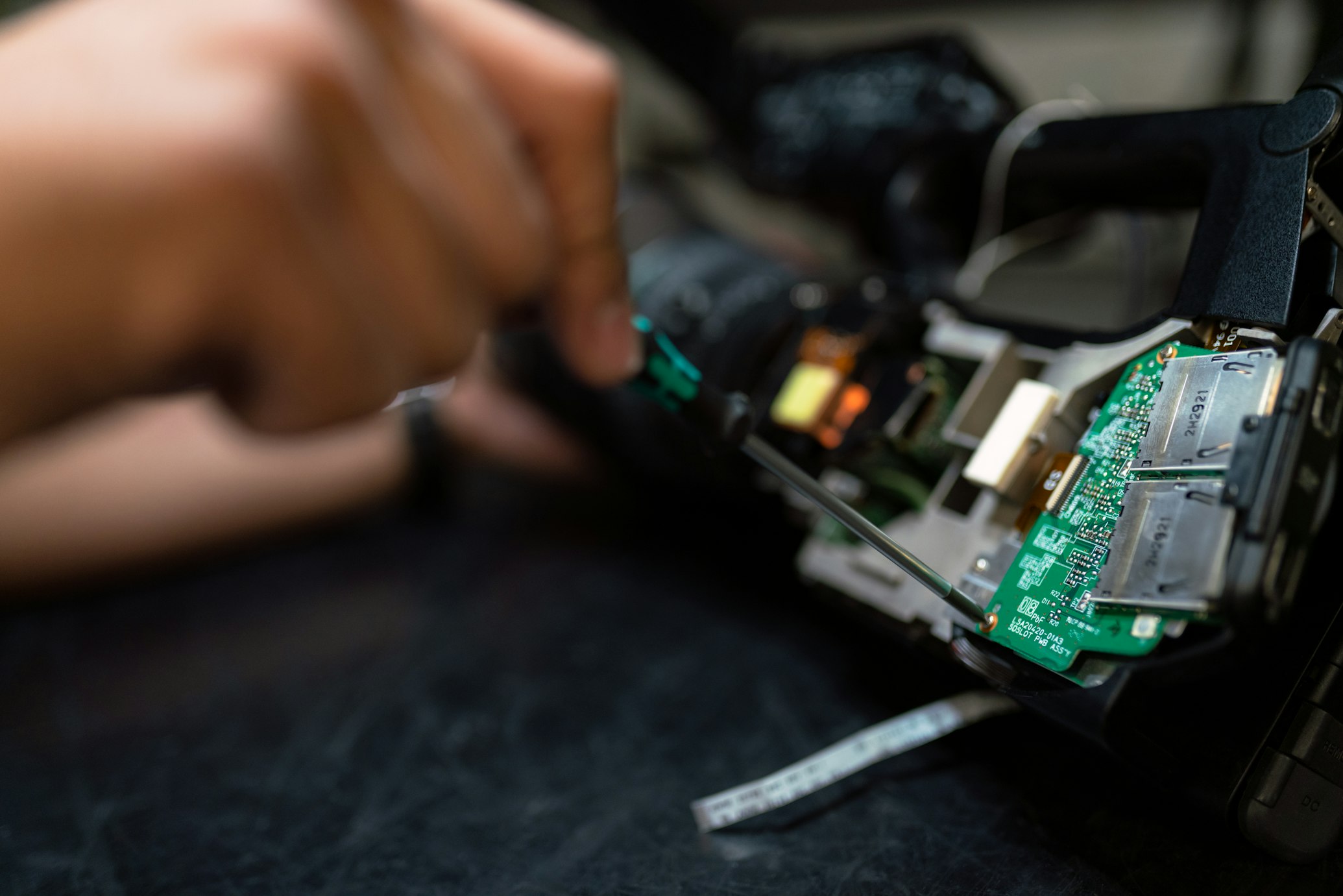

High-performance automotive impellers

Complex injection mold design

Flow dynamics testing process

Performance testing facility

Ready to Start Your Injection Molding Project?

Let's discuss how our precision injection molding capabilities can bring your product vision to life with exceptional quality and efficiency.