Button Grease

Precision Button Component Manufacturing

Client

Electronics Manufacturer

Year

2023

Micro-Precision Components with Integrated Lubrication

Our client required extremely precise button components with integrated grease channels for smooth operation and extended lifespan. The tolerances were critical - even minor variations could affect tactile feel and operational reliability.

The components needed specialized grease channels that would distribute lubrication evenly while preventing contamination. Traditional machining methods were too slow and expensive for the required volumes.

Quality control was paramount, as these components were destined for high-end electronic devices where button feel directly impacts user experience.

Micro-Injection Molding with Integrated Channels

Stone Plastics developed a micro-injection molding process using POM (Delrin) material for optimal wear resistance and dimensional stability. We created ultra-precise tooling with integrated grease channel formation.

Our process includes specialized injection parameters optimized for thin-wall sections and micro-features. Advanced quality control systems verify dimensional accuracy and channel integrity on every part.

The solution included: • Micro-injection molding with ±0.001 inch tolerance • Ultra-precise tooling for grease channel formation • POM material selection for wear resistance • 100% automated dimensional inspection • Specialized grease application and testing • Clean room manufacturing environment

Key Outcomes

500,000+ button components per month

±0.001 inch dimensional tolerance achieved

100% pass rate on tactile feel testing

Integrated grease channels eliminate assembly step

50% cost reduction vs. machined alternatives

The precision and consistency of Stone Plastics' button components has been remarkable. The integrated grease channels have significantly improved our product reliability and user satisfaction.

Jennifer Liu

Quality Engineering Manager, TechPrecision Electronics

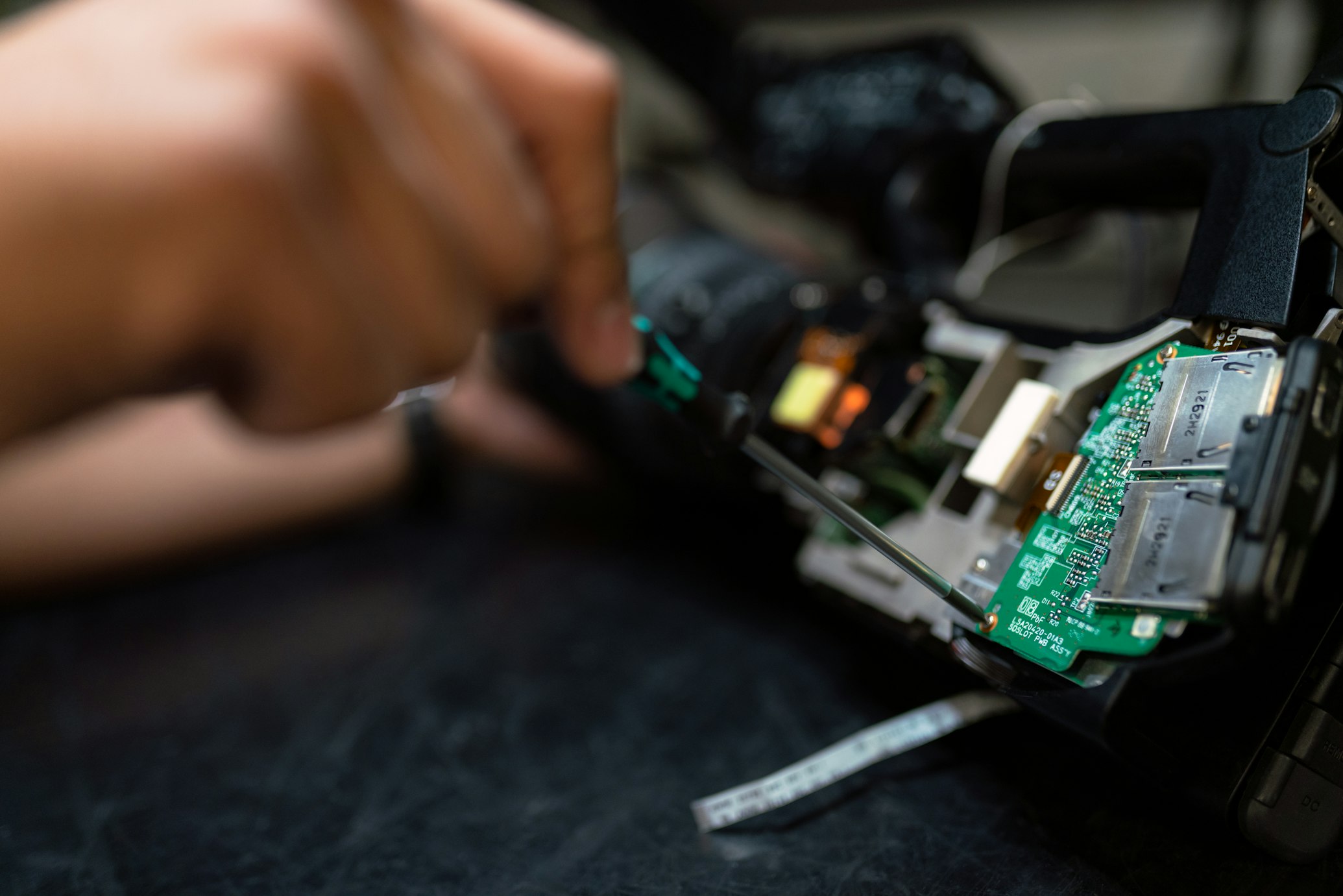

Project Gallery

Precision button components with grease channels

Micro-injection molding equipment

Precision manufacturing process

Automated quality inspection system

Ready to Start Your Injection Molding Project?

Let's discuss how our precision injection molding capabilities can bring your product vision to life with exceptional quality and efficiency.