Case Studies

Explore our precision injection molding projects showcasing advanced manufacturing techniques, innovative materials, and exceptional quality control across diverse industries.

Injection Molding Excellence

Discover how our advanced injection molding capabilities and precision manufacturing processes have helped clients achieve exceptional results across various industries and applications.

806 Epoxy

High-Performance Epoxy Component Manufacturing

Precision injection molding of 806 epoxy components with tight tolerances and superior chemical resistance for industrial applications.

Helmet

Safety Helmet Shell Production

Large-scale injection molding of safety helmet shells using impact-resistant polymers with integrated ventilation systems.

Foam Buddy

Foam Integration Molding System

Advanced insert molding technique combining rigid plastic components with foam inserts for enhanced comfort and functionality.

Button Grease

Precision Button Component Manufacturing

Micro-precision injection molding of button components with specialized grease channels for smooth operation and longevity.

Impeller (301)

High-Performance Impeller Manufacturing

Complex geometry injection molding of automotive impellers with optimized flow dynamics and superior durability.

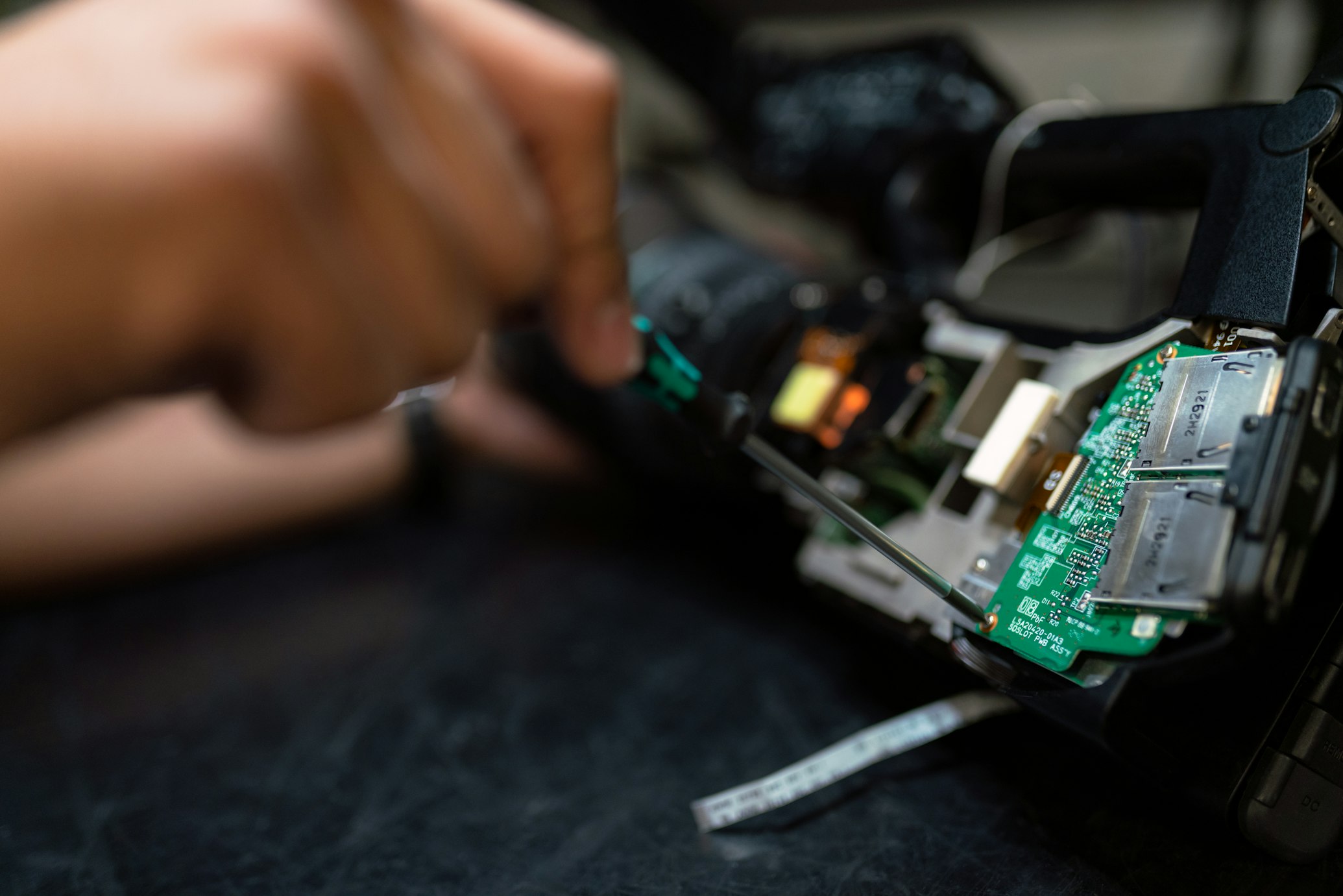

Microphone Housing

Acoustic Component Manufacturing

Precision injection molding of microphone housings with acoustic optimization and electromagnetic interference shielding.

Our Injection Molding Process

From concept to production, we utilize state-of-the-art injection molding equipment ranging from 5-ton to 500-ton presses, ensuring optimal production for any project size.

- Material selection and validation

- Precision tooling design and manufacturing

- Process optimization and quality control

- Full-scale production and assembly

Ready to Start Your Injection Molding Project?

Let's discuss how our precision injection molding capabilities can bring your product vision to life with exceptional quality and efficiency.

Start Your Project