Helmet

Safety Helmet Shell Production

Client

Safety Equipment Manufacturer

Year

2023

Large-Scale Production of Impact-Resistant Helmet Shells

Our client needed to scale production of safety helmet shells that met stringent impact resistance standards while maintaining lightweight properties. The challenge was achieving consistent wall thickness and structural integrity across large production volumes.

The helmet shells required integrated ventilation systems and mounting points for accessories, adding complexity to the molding process. Quality standards demanded zero tolerance for structural defects that could compromise safety.

Production volumes of 100,000+ units annually required efficient processes and minimal waste to maintain competitive pricing.

High-Volume Injection Molding with Integrated Features

Stone Plastics implemented a large-tonnage injection molding solution using ABS/PC blend materials optimized for impact resistance. We designed multi-cavity tooling to maximize production efficiency while maintaining part quality.

Our process included integrated molding of ventilation channels and mounting features, eliminating secondary operations. Advanced process monitoring ensured consistent wall thickness and structural integrity.

The solution included: • Large-tonnage injection molding presses (300+ ton) • Multi-cavity tooling for high-volume production • Integrated ventilation and mounting feature molding • Real-time process monitoring and control • Automated quality inspection systems • Impact resistance testing protocols

Key Outcomes

100,000+ helmet shells produced annually

±0.005 inch wall thickness consistency

100% pass rate on impact resistance testing

Integrated features eliminate 3 secondary operations

30% reduction in production cost per unit

The quality and consistency of helmet shells from Stone Plastics has been exceptional. Their ability to integrate complex features during molding has streamlined our entire production process.

Sarah Chen

Production Director, SafeGuard Equipment

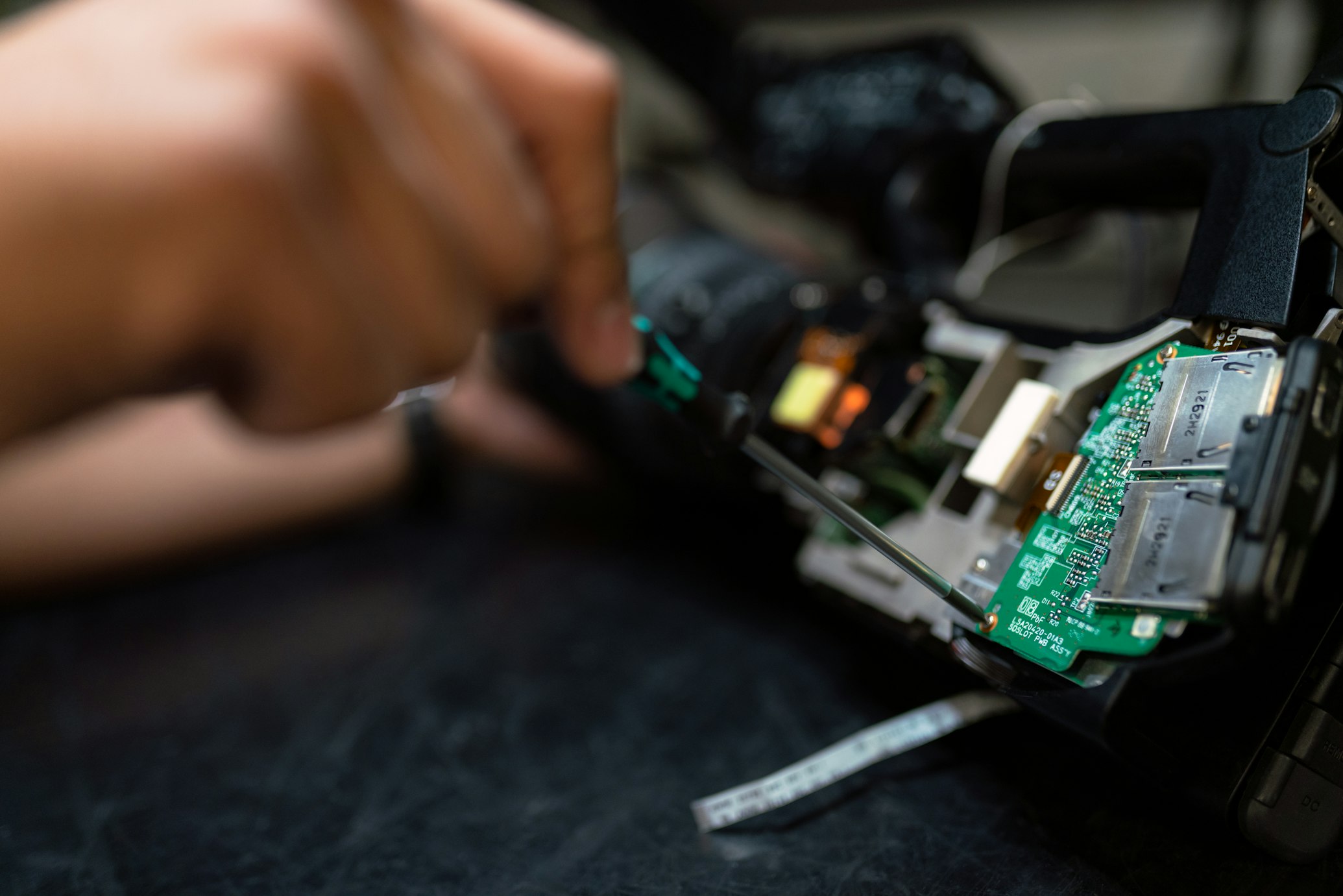

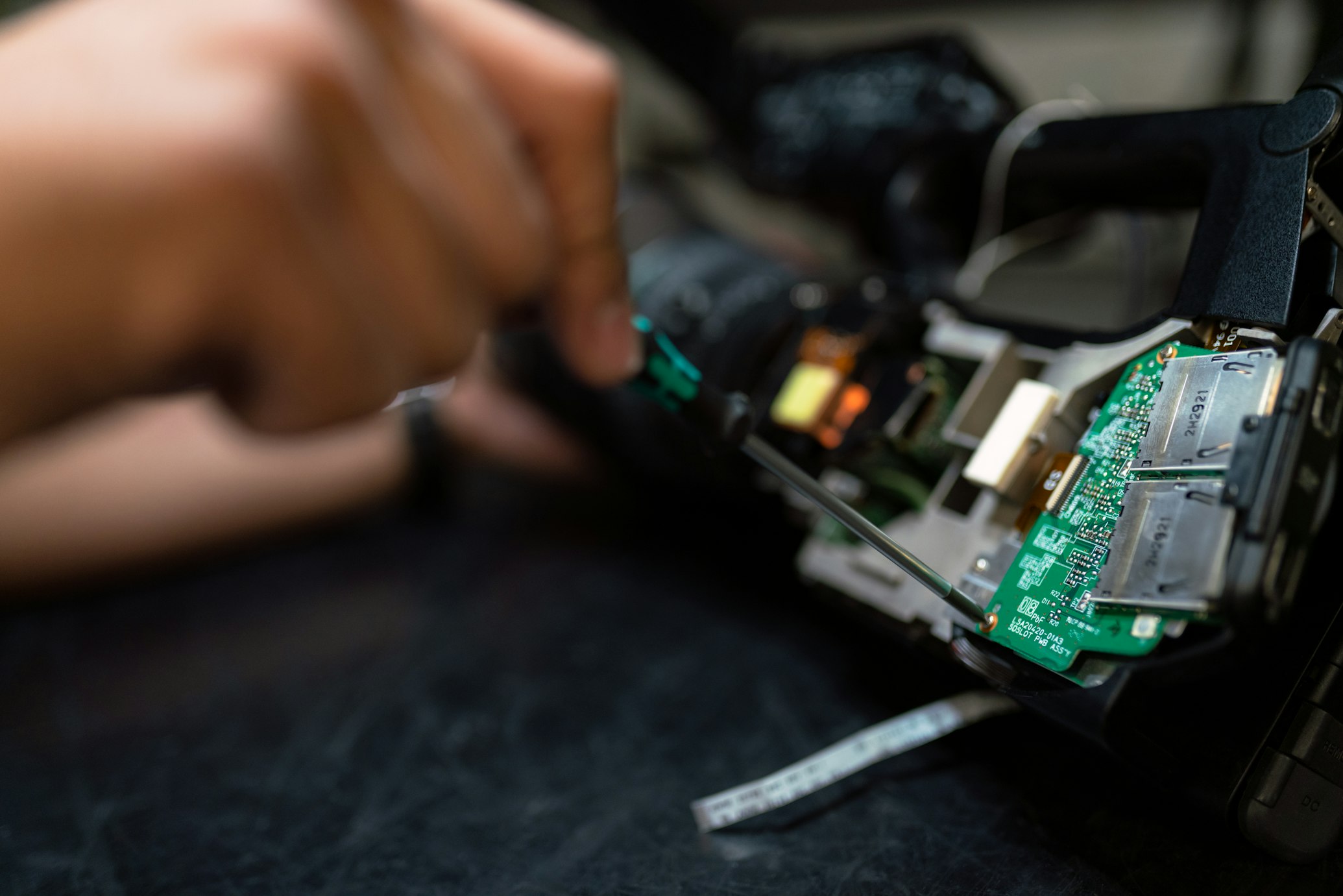

Project Gallery

Completed safety helmet shells

Multi-cavity injection mold

High-volume production line

Impact resistance testing facility

Ready to Start Your Injection Molding Project?

Let's discuss how our precision injection molding capabilities can bring your product vision to life with exceptional quality and efficiency.