806 Epoxy

High-Performance Epoxy Component Manufacturing

Client

Industrial Equipment Manufacturer

Year

2023

Precision Molding of Chemical-Resistant Components

Our client required high-performance epoxy components that could withstand extreme chemical environments while maintaining precise dimensional tolerances. The 806 epoxy material presented unique challenges in terms of processing temperature, cure time, and mold release.

Traditional manufacturing methods were unable to achieve the required surface finish and dimensional accuracy. The components needed to maintain their properties under continuous exposure to aggressive chemicals and elevated temperatures.

Additionally, the production volume requirements demanded a repeatable process that could deliver consistent quality across thousands of parts.

Advanced Injection Molding with Temperature Control

Stone Plastics developed a specialized injection molding process using precision temperature control and custom tooling designed specifically for 806 epoxy. We implemented a multi-stage heating system to ensure optimal material flow and cure characteristics.

Our engineering team created specialized mold designs with advanced cooling channels and release mechanisms to prevent part damage during ejection. We also developed a comprehensive quality control process including chemical resistance testing.

The solution included: • Custom temperature-controlled injection molding process • Specialized tooling with advanced release mechanisms • Multi-point quality inspection system • Chemical resistance validation testing • Automated handling systems to prevent contamination

Key Outcomes

Achieved ±0.002 inch dimensional tolerance consistently

100% chemical resistance compliance in testing

50,000+ units per month production capacity

Zero defects in critical dimensions

25% reduction in production time vs. alternative methods

Stone Plastics' expertise in handling specialized materials like 806 epoxy has been invaluable. Their precision and attention to detail ensure our components meet the most demanding industrial requirements.

Michael Rodriguez

Engineering Manager, Industrial Solutions Inc.

Project Gallery

Finished 806 epoxy components

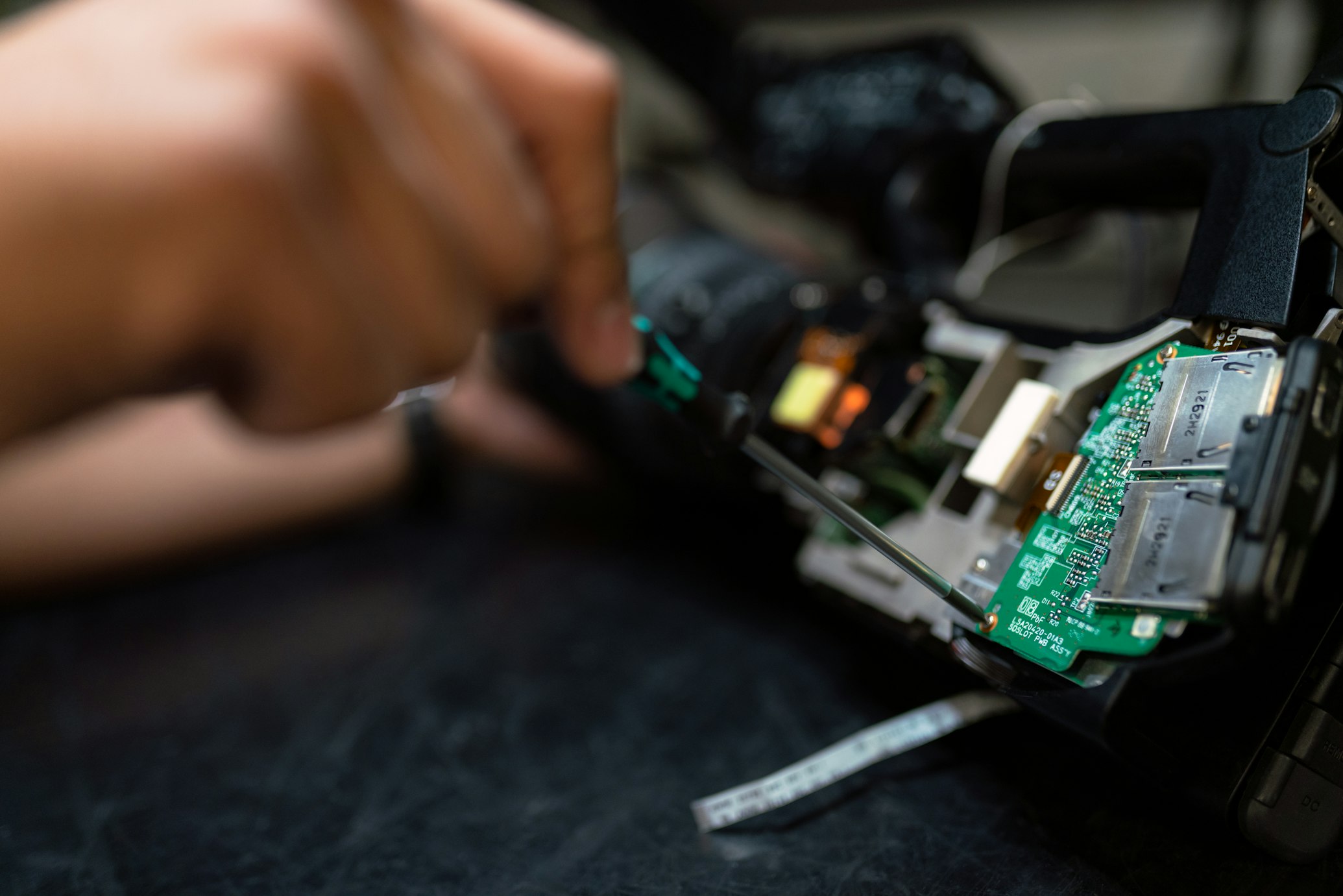

Specialized injection molding setup

Manufacturing process overview

Quality control and testing

Ready to Start Your Injection Molding Project?

Let's discuss how our precision injection molding capabilities can bring your product vision to life with exceptional quality and efficiency.