Foam Buddy

Foam Integration Molding System

Client

Consumer Products Company

Year

2023

Combining Rigid Plastics with Foam Inserts

Our client needed a manufacturing solution that could seamlessly integrate foam inserts with rigid plastic components for enhanced comfort and functionality. Traditional assembly methods resulted in inconsistent bonding and reduced durability.

The challenge was developing a process that could mold around pre-placed foam inserts without damaging the foam or creating weak bond lines. The final product required consistent compression characteristics and long-term durability.

Production efficiency was critical, as manual assembly processes were too slow and inconsistent for the required volumes.

Advanced Insert Molding with Foam Integration

Stone Plastics developed an innovative insert molding process that allows foam components to be placed in the mold before injection. We created specialized tooling with precise foam positioning systems and optimized injection parameters.

Our process uses TPU materials that bond effectively with foam while maintaining flexibility. Temperature and pressure controls ensure the foam maintains its properties while achieving strong mechanical bonds.

The solution included: • Specialized insert molding tooling with foam positioning • TPU material selection for optimal foam bonding • Precise temperature and pressure control systems • Automated foam placement systems • Compression testing and validation protocols • Quality control for bond strength and durability

Key Outcomes

25,000+ units per month production capacity

±0.003 inch dimensional tolerance on plastic components

95% improvement in foam-to-plastic bond strength

Eliminated 2 secondary assembly operations

40% reduction in production time vs. assembly methods

Stone Plastics' foam integration process has revolutionized our product design. The seamless bonding and consistent quality have exceeded our expectations and improved our customer satisfaction significantly.

David Park

Product Development Manager, Comfort Solutions LLC

Project Gallery

Completed foam-integrated components

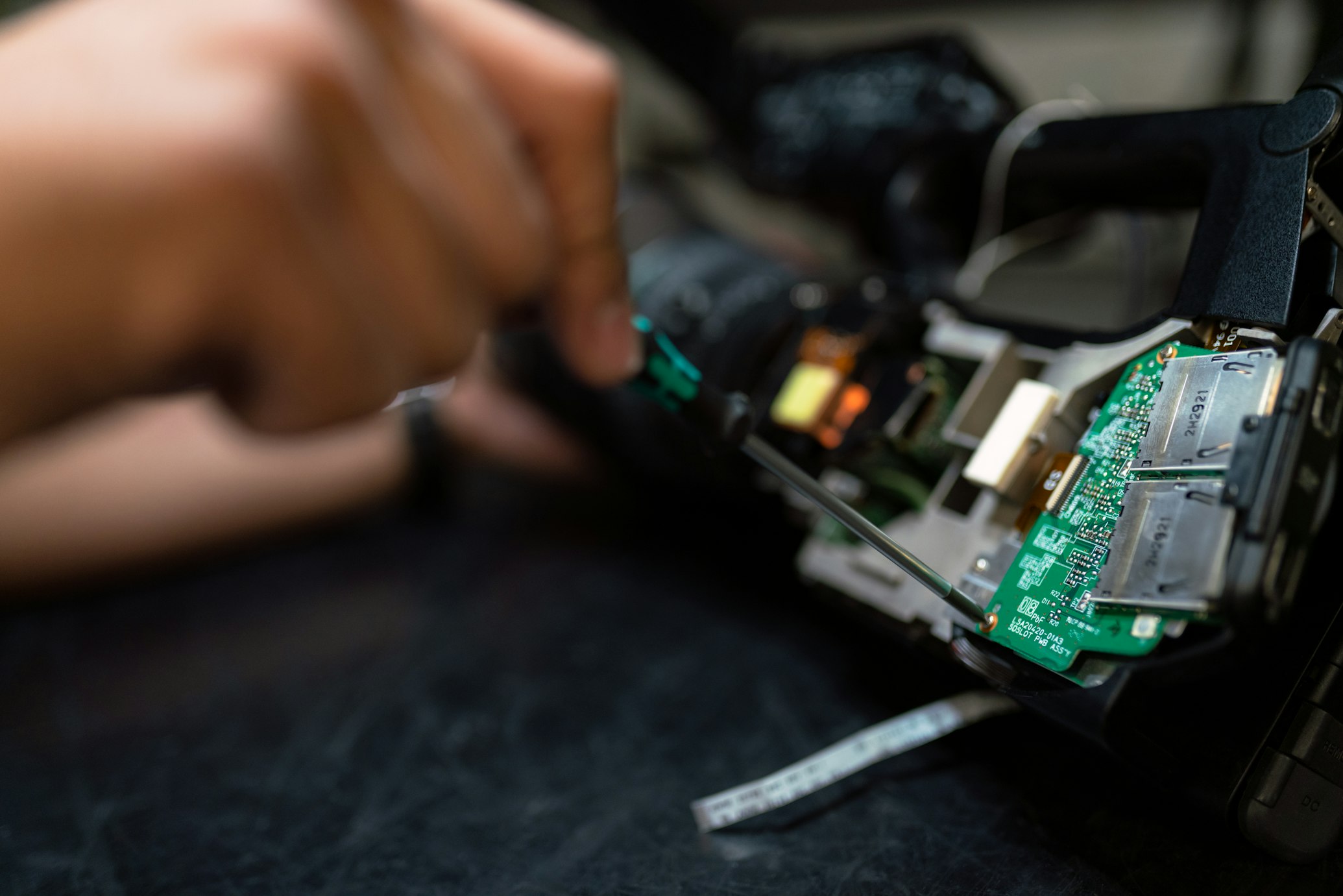

Insert molding machine setup

Foam integration molding process

Bond strength testing laboratory

Ready to Start Your Injection Molding Project?

Let's discuss how our precision injection molding capabilities can bring your product vision to life with exceptional quality and efficiency.